Story and illustrations by Mackenzie Manley

What Is It?

Lean manufacturing represents the purest, most efficient form of manufacturing. Drawing inspiration from Toyota's Production System, Lean emphasizes pull systems and visual tools to align organizational efforts, minimizing waste and inefficiency. One of these tools, called Kanban (meaning "card" or "signal"), originated from supermarket shelf-restocking practices—what gets sold is swiftly restocked. Toyota adopted this method for its factories and supply chains, and other successful manufacturers, like Waterstone Faucets, have embraced it too.

How Does It Actually Work?

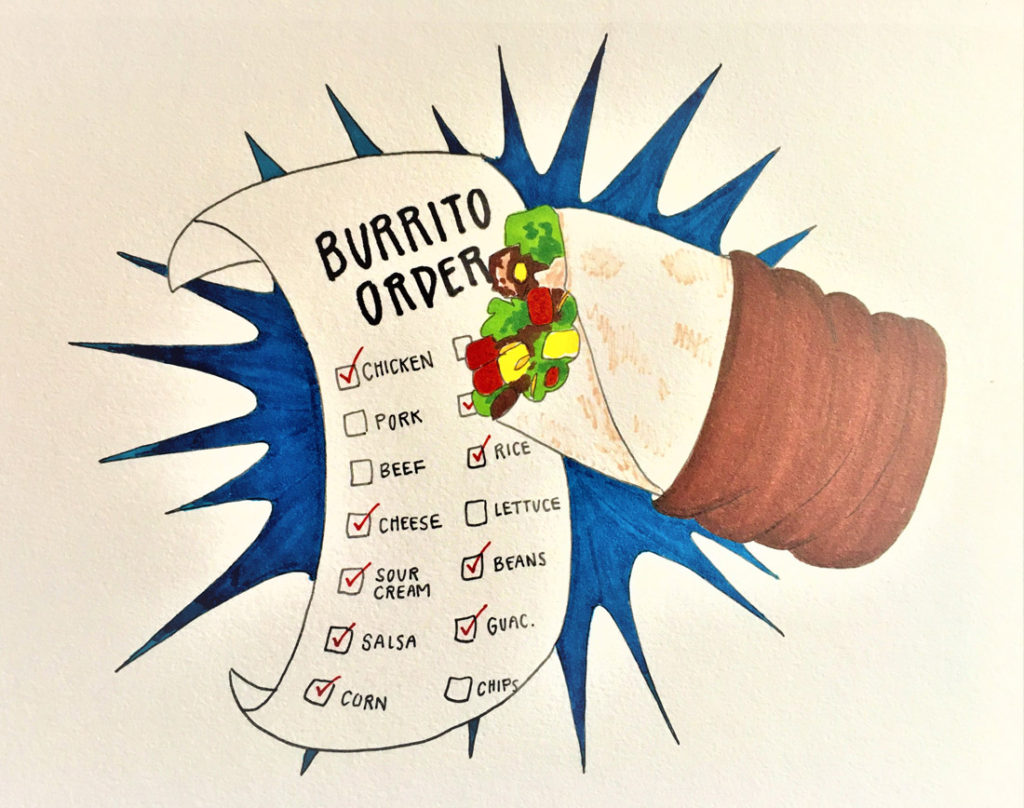

To understand Kanban, think of it as a Pull System. When you need a specific part, you "pull" it from the bin labeled for that part. These bins are stocked with precisely the quantity needed that day to produce goods. A creative example of a Kanban system—or lean manufacturing—is your local burrito joint! Let's break down the process step by step:

Step 1.

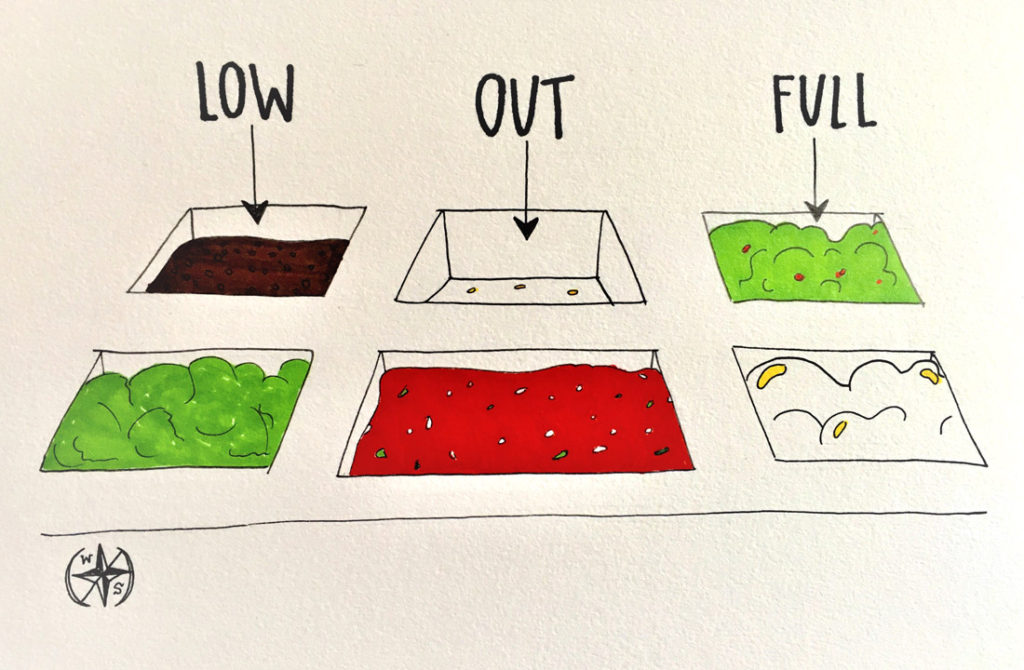

You're on your lunch break, craving a delicious burrito. You head to your favorite burrito shop, which prepares burritos fresh in front of you. You can pick your own ingredients, and each one is stored in its own bin. These bins aren't overly large—they likely hold enough ingredients to last through the lunch rush.

Step 2.

As you select your ingredients, Mike, the burrito maker, gathers each item he needs to complete your burrito. Some bins are running low, but when you reach the cheese station, Mike notices that the cheese has completely run out.

Step 3.

Mike takes the empty cheese bin back into the kitchen and swaps it for a full one. This full bin was prepared earlier by Mike, who noticed several customers coming through and realized the cheese was running low. Mike quickly shredded the cheese to refill the bin because all the necessary tools—the cheese, the shredder, and gloves—are kept in the exact same spots in the kitchen, allowing him to locate them easily and work efficiently.

Step 4.

Mike returns with the full cheese bin, places it back where it belongs, and resumes building your burrito. Once you've chosen all your ingredients, Mike wraps the burrito and hands it to you in a container to take back to work. The transaction is seamless, and you leave satisfied with a quick, accurate meal!

The Kanban System at Waterstone:

Similar to a burrito shop, Waterstone uses the Kanban system in its inventory management. Instead of bins of ingredients, they have bins of faucet parts. All parts are machined in their Southern California factory so that bins can be replenished as needed. When a customer orders a faucet or suite, the Kanban or lean manufacturing system kicks into action. Waterstone also prioritizes organization. Every tool has its designated spot, and a well-organized workspace ensures faster, more efficient production, allowing customers to receive their orders quicker!

Chris Kuran, Waterstone's president, initially hesitated before transitioning from their complex inventory system to the simpler Kanban or lean manufacturing approach. "I didn't realize there was an easier and better way to manage inventory. Once I learned about the benefits of Kanban, I knew it would be perfect for us since we’re a smaller business producing everything in-house."

The Kanban system addressed a complex issue with a straightforward solution. Waterstone has leveraged Japanese wisdom to tackle significant challenges, but Kanban can also be applied on a smaller scale—perhaps even in your own kitchen! Stay tuned to discover how implementing the Kanban system (with Waterstone's guidance) can streamline your kitchen experience!

Komatsu Parts,Komatsu Spare Parts,Genuine Komatsu Parts,High Quality Komatsu Parts

JINING SHANTE SONGZHENG CONSTRUCTION MACHINERY CO.LTD , https://www.stszcmparts.com