Tractor & Farm Accessories

Red Head Hitch Pins are used for coupling implements and machinery. Forged hitch pins are made from high strength steel and heat treated. Hitch Pin have powder coating with a red vinyl coated head and handle, zinc plated "R" Clip pin included.

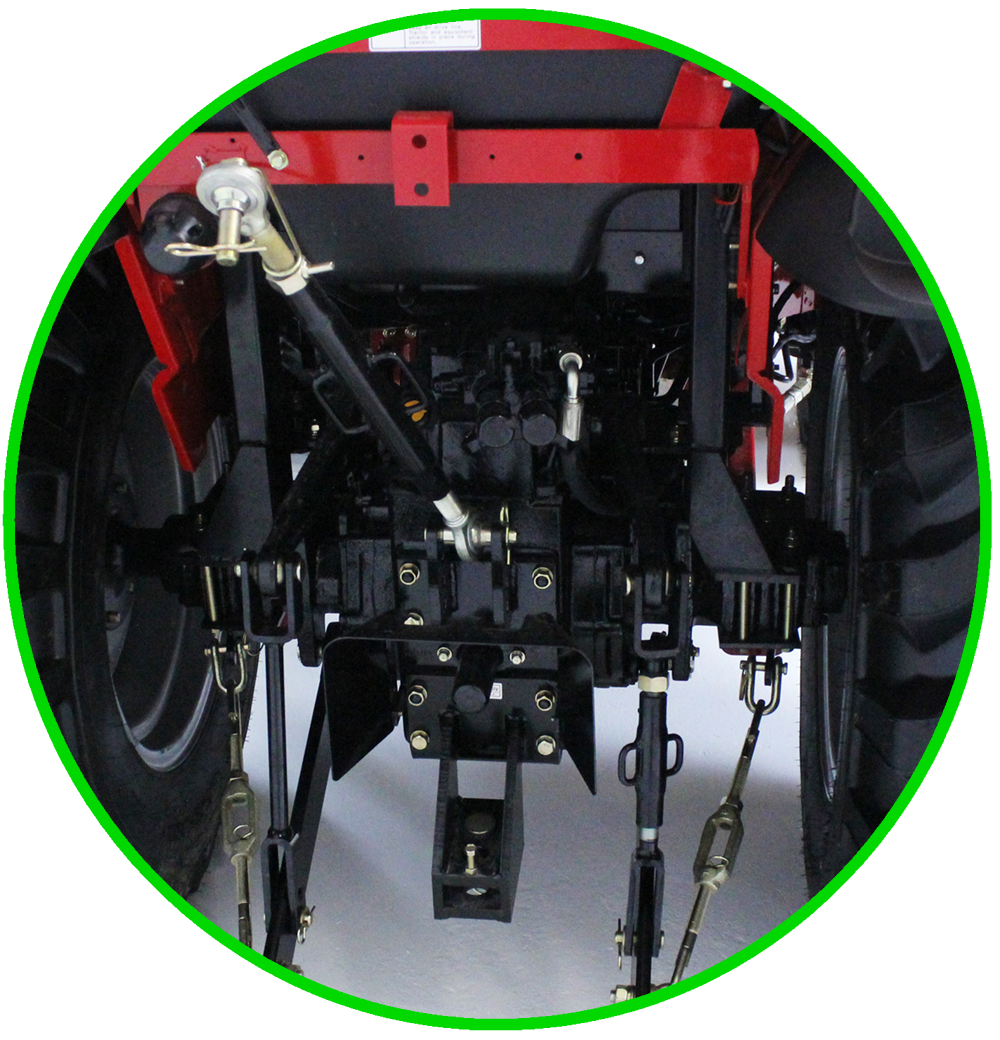

Forged Hitch Pins are used to attach trailers and various turf and agricultural implements. Manufactured from forged steel with swivel handle and zinc plated, come with R clip pin or Lynch pin and chain.

Lynch Pins are designed with a solid pin with an attached self-locking ring. This ring allows the pin to be securely held in place and provides an easy grip for quick removal.

Hitch, Lynch Pin, Wire Lock, Linkage, 3 point Pin,greenhouse structure,Red head,Weld-on Hinge,Cross Connector,Fasteners,Forged,Linch Pin,bars,trucks,Greenhouse,Antiluce,lift off hinge,Hinge pins,Welding hinge,steering system, Cam Lock,loader pin,weld on

Ningbo Yokelink Machinery Co.,Limited , https://www.yokelink.com