Hooks are a critical component in most rigging applications. There are various types of hooks available, each suited for different purposes. While some hooks excel in securing loads, others are better for lifting tasks. In this video, we'll explore the different types of hooks and their ideal uses.

Latch or No Latch?

Safety latch hooks are widely regarded as the industry standard for rigging operations. According to OSHA standards, safety latch-equipped hooks should be used unless their presence hinders the operation. Although we do sell non-safety hooks on our site, this article will focus primarily on safety-latch hooks, particularly those where a latch would interfere with functionality.

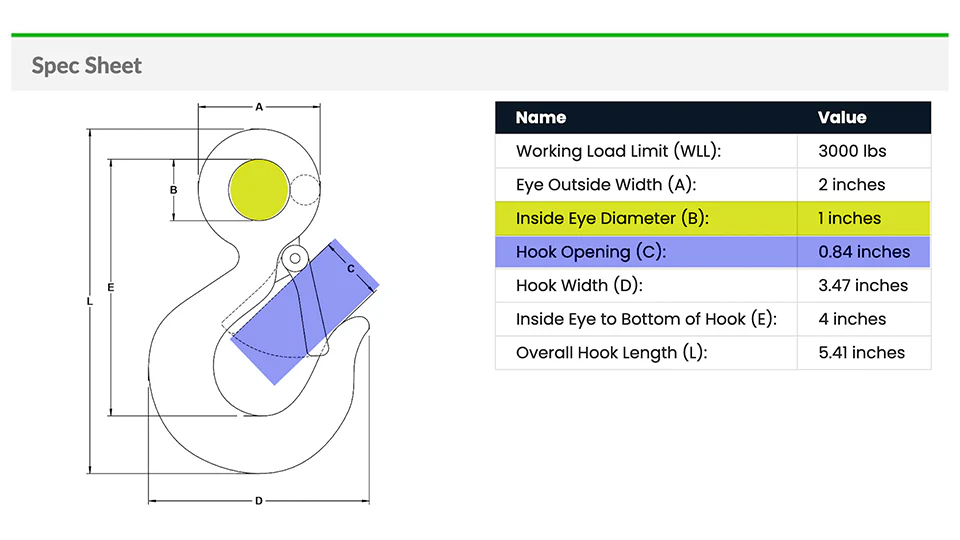

Working Load Limits and Dimensions

The size and shape of most hooks are determined by their Working Load Limit (WLL). Our website offers hooks with capacities ranging from 220 lbs. to 7 tons. Additionally, factors such as the hook's diameter and opening are important considerations. It's advisable to measure the rigging tools and fittings intended to connect to the hook, then cross-check these measurements against the product specification sheets to ensure you select the correct hook for your needs.

Safety Hoist Hook

This versatile hook is commonly used in lifting and pulling applications and is often found in the toolkits of rigging professionals. Its design allows for easy attachment and detachment from other rigging components, making it one of our most popular offerings.

Swivel Hoist Hooks

These hooks function similarly to standard hoist hooks but include a swivel mechanism at the top. This allows the user to adjust the hook's orientation before lifting. However, it's important to note that these hooks should not be rotated while under load. Always ensure the swivel is set to the desired position prior to lifting.

Grab Hooks

Grab hooks are typically found at the ends of chains or ratchet load binders, used for securing and hauling loads. These hooks feature an opening that corresponds to specific chain sizes (such as Grade-70 Transport Chain). Unlike traditional hooks with eyes or swivels, grab hooks have a clevis-style attachment, making them easy to secure to transport chains and binders.

Can I Replace the Safety Latch on Safety Hooks?

Safety latches are prone to wear and tear, and they can bend or break, rendering them inoperable. Since these are non-load-bearing components, they are relatively easy to replace without affecting the overall hook performance. Before replacing the latch, inspect the hook for any additional damage, such as warping or cracks. If the hook passes inspection, you can purchase a third-party latch replacement kit. Please note that we do not currently offer replacement latch kits at E-Rigging.

Can I Replace the Safety Hook on My Hoist or Puller?

Many of the hooks we offer may be compatible with devices like lever load hoists or cable pullers. Replacing a hook on such lifting tools involves inspecting the hoist or puller for any additional damage. If the device is damaged beyond repair, it should be sent to a professional for servicing or replaced entirely. If the damage is limited to the hook, check if it can be replaced. In many cases, the hook is held in place by a pin and can be easily swapped with a comparable hook. If the hook is permanently attached to the cable or chain, replacing the entire unit may be necessary.

For more information on rigging equipment and load binding, click here.

Remember, safety should always be your top priority when working with rigging tools. Regular maintenance and inspections are crucial to ensuring the longevity and reliability of your equipment. If you have any questions about selecting the right hook for your application, don't hesitate to reach out to our team of experts.

Vinyl Flooring,Vinyl Plank Flooring,Engineered Flooring,Lvt Vinyl Plank

Changzhou Yingda New Material Co., Ltd , https://www.yingdaspc.com