Hydropower renovation is a crucial part of modern home upgrades, and it's also one of the most hidden projects in the process. Unfortunately, it's also a common source of problems during renovations. So, what are the key points to consider when renovating hydropower systems? Industry experts have highlighted three main areas that should not be overlooked.

First and foremost, it's essential to separate strong and weak electrical wiring and route them properly. It’s strictly prohibited to use the same pipe or junction box for both types of wiring. Mixing strong electricity (like lighting cables) with weak electricity (such as telephone or network lines) can cause signal interference, leading to poor communication and even fire hazards if too many wires are crammed into one conduit.

Secondly, all wiring should be protected by an insulating sleeve, and all connections must be securely enclosed within junction boxes. Exposed wire joints are extremely dangerous and should never be left visible. During construction, some people may directly bury wires in walls without using protective sleeves, or leave connectors exposed—this can lead to serious safety risks, including electric shocks and short circuits due to aging cables.

Lastly, when it comes to water pipeline renovation, special attention should be given to different areas of the house. In bathrooms, for example, careful planning is needed for the placement of sinks, toilets, bathtubs, and washing machines. You must determine whether hot water pipes are required and ensure proper drainage for floor drains to avoid backflow issues. In the kitchen, the focus is usually on faucets and water heaters. Since kitchens and bathrooms often share a single water heater, the installation location must be planned in advance to determine where hot and cold water pipes will go, ensuring smooth water system upgrades.

By following these guidelines, homeowners can significantly reduce the risk of future problems and ensure a safer, more efficient home environment after renovation.

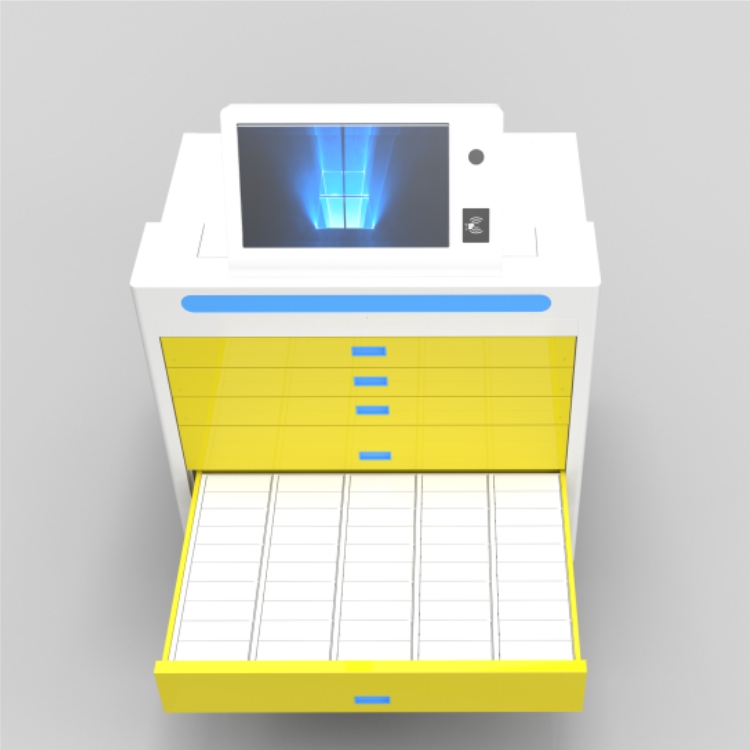

Intelligent Tool Cabinet,64 Door Grid Cabinet,Intelligent Grid Tool Cabinet

Jiangsu Xicang Intelligent Technology Co., Ltd. , https://www.xciwarehousing.com